How it works

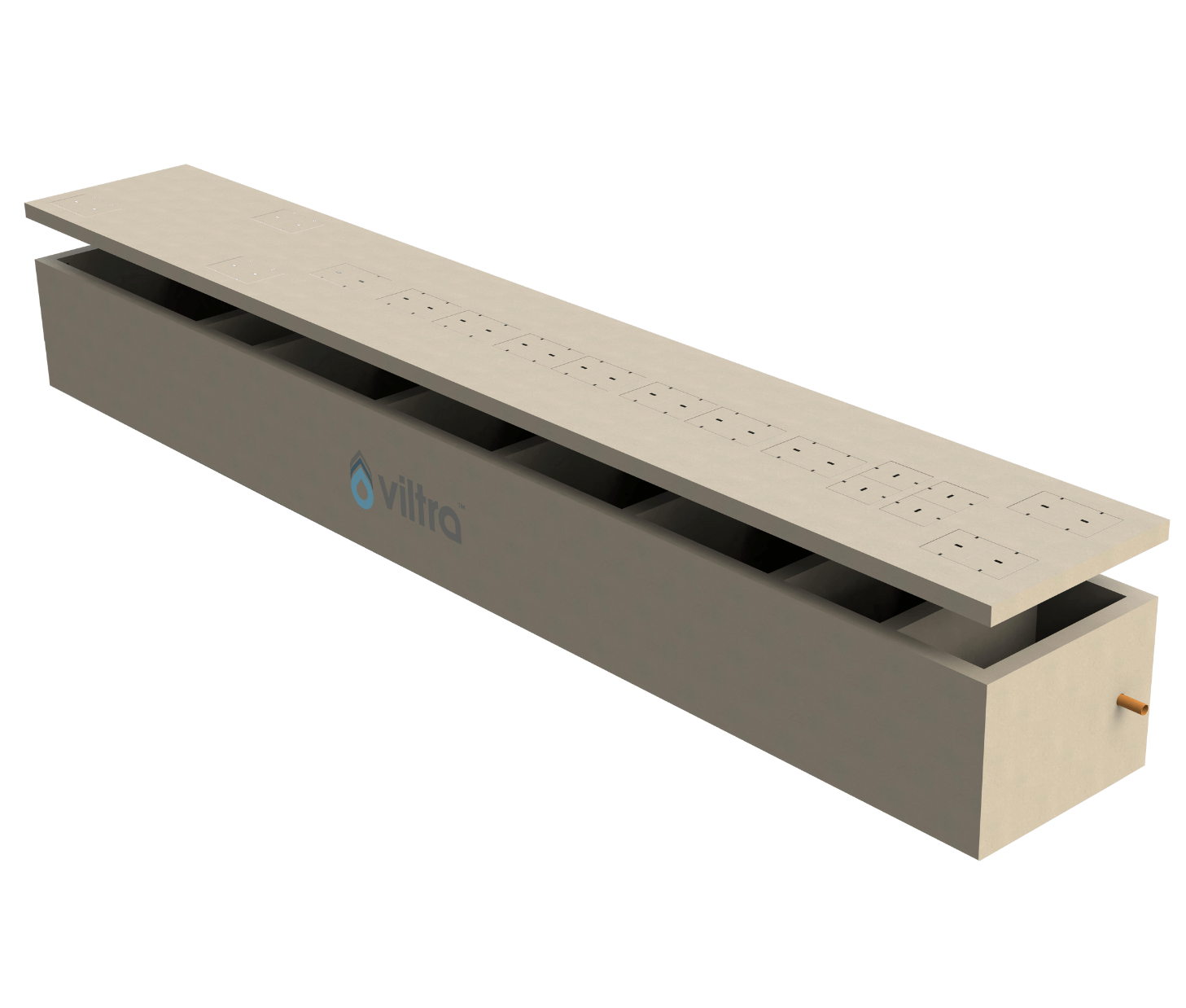

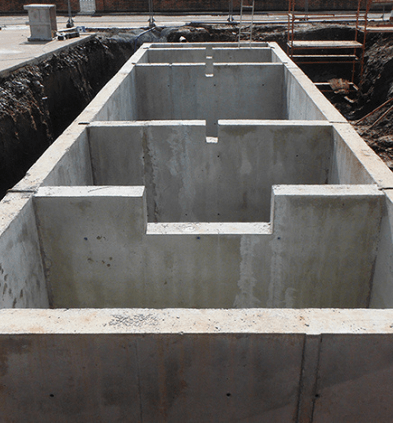

Viltra's OXCRETE PLUS is a 3-stage sewage treatment plant in multiple concrete structures.

Primary Settlement Tank (PST)

The Primary Settlement Tank is designed to maximize the removal of gross and suspended solids prior to transfer of the settled effluent to biological treatment. The PST is made up of two chambers before the settled wastewater is transferred via an air lift into the Biological Treatment followed by the Final Settlement Chamber. The PST Sedimentation area will remove large and heavy solids such as paper, food and any fast-settling solids.

Biozone (BZ)

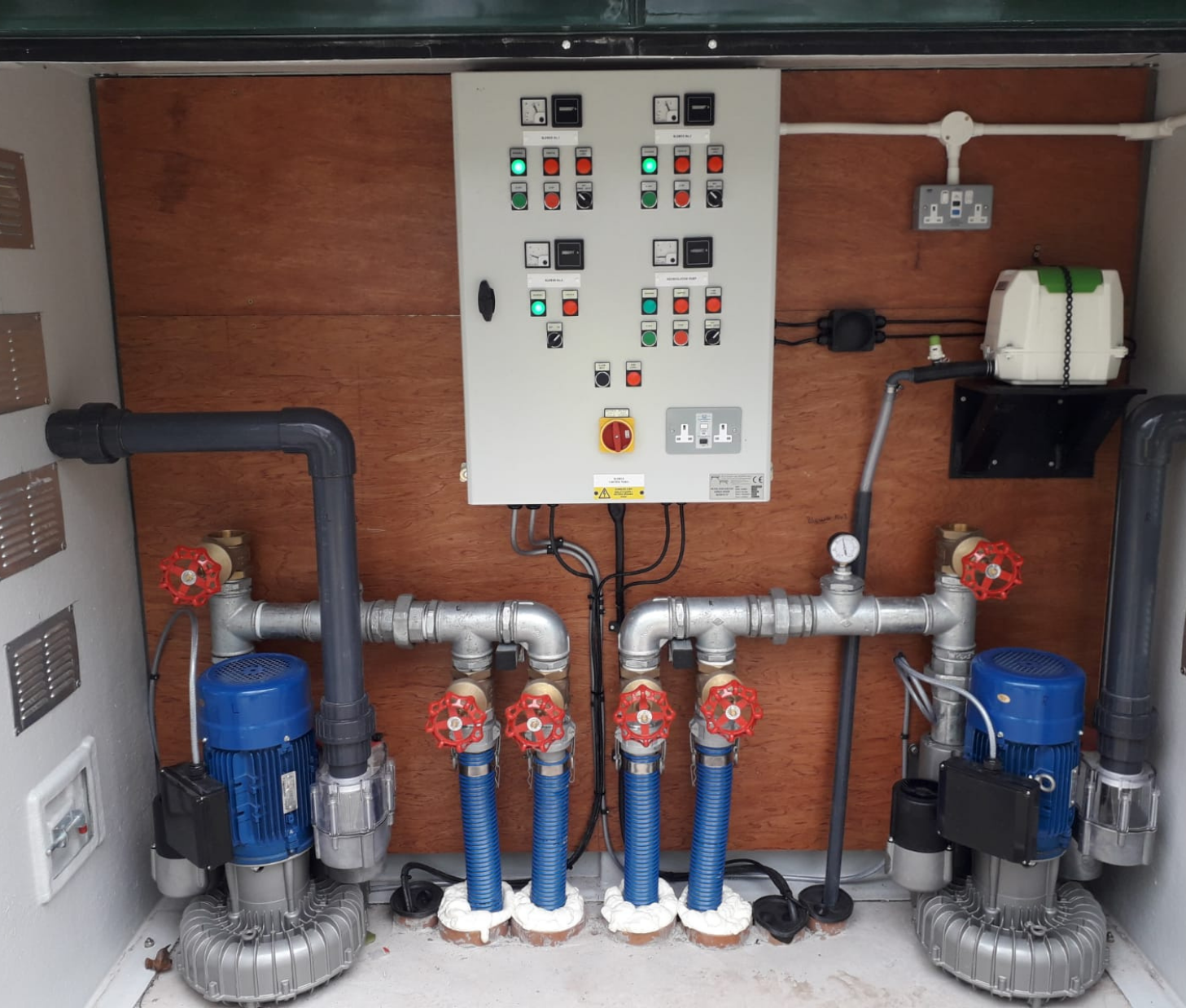

The Biological Treatment phase utilises biological SAF technology (Biological Submerged Aerated Filter) which incorporates two proven principles of biological process in the form of a fixed film reactor for process stability and a suspended flock dispersed growth system for high transfer rates and operational control, to ensure a stable treatment process which is largely unaffected by shock loads.

The process incorporates a submerged, high rate, plastic media on which a fixed film of biomass is grown. This film takes nutrition from the incoming settled effluent and is provided with oxygen by means of a blower unit which aerates the media and the water through EPDM fine bubble membrane diffusers.

The action of the fine bubble aeration is carefully designed to provide optimum oxygen transfer rates and to provide a scouring action to slough off excess biomass, keeping the thickness of the fixed biological film at optimum levels, thereby preventing the production of anaerobic bacteria and ensuring maximum process efficiency.

The fact that the media remains submerged allows for an element of suspended flock dispersed growth which basically means that there will be biomass which is “unfixed” to the media but achieves treatment through suspended aeration.

Final Settlement Tank (FST)

The FST is designed to ensure relevant surface areas and raise rates are achieved to provide maximum settlement of any suspended solids prior to discharge.

The final settlement tank incorporates a continuous and automated sludge return system to return excess sludge from the final settlement tank, back to the primary settlement tank.

Additionally, the system also provides for continuous recycling of treated effluent back to the P.S.T. to not only provide dilution of incoming settled effluent but to also ensure continuous flow during periods of low or no flow, thereby keeping the biomass in prime condition.

Key features

-

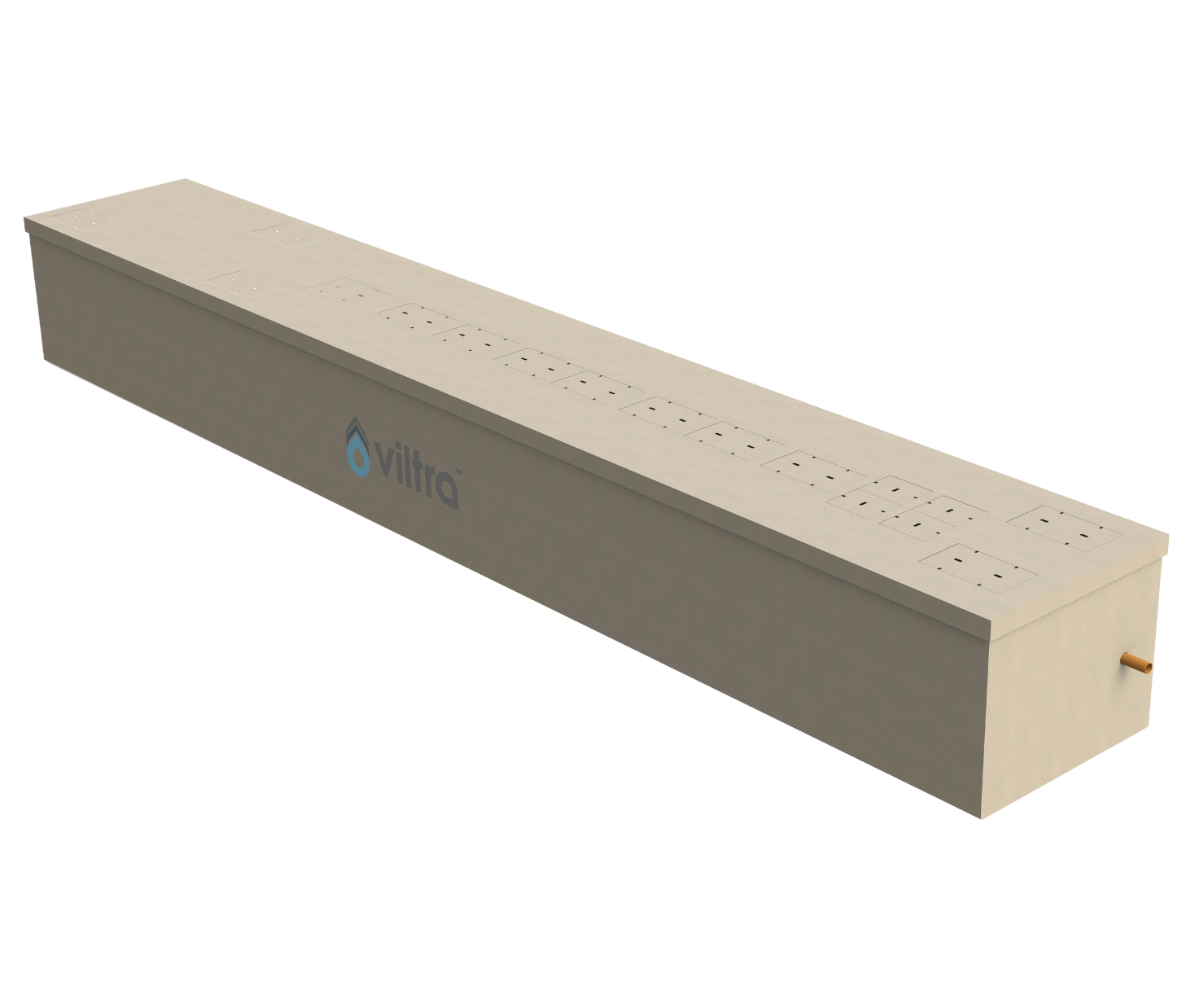

Pre-cast concrete tank which is CE certified to EN 206-1 concrete mix which covers water tightness, durability and crushing resistance

-

Supplied as standard with flush B125 concrete infill access covers

-

Can be designed for HGV traffic

-

Bespoke design tailored to fit your site

-

Designed to achieve the strictest effluent qualities

-

Designed to treat both trade and domestic effluent

-

Failure alarm system as standard and not at additional cost

-

Sealed unit with no joints below water level

-

Our unique flow buffering technology (ALF) ensures a constant steady flow 24 hours a day through your system with a gradual release to the natural environment

-

Removal efficiencies up to 99.2%

Environment Agency Standard

Why choose a Viltra sewage treatment plant?

-

Bespoke created products that are created in the UK and Ireland

-

Superior products and services that are suitable to our customer's requirements

-

Established track record of providing cost-effective and competent sewage treatment plants within the wastewater market across the UK and Ireland

-

Our bigger commercial and industrial products are always supported up our process warranty

-

Completely comprehensive mechanical and electrical installation with technical assistance from design through to installation and final commissioning

-

We take care of the Consent to Discharge process for you, liaising with the all-regulatory bodies to safeguard compliance with any requirements enforced

-

At Viltra are proud to have a team of committed process, civil, electrical, mechanical and environmental engineers with comprehensive experience in the wastewater industry

-

We offer reliable after-sales service to give our customers clarity and reassurance

-

24-hour emergency breakdown service

-

Servicing and maintenance packages available at affordable prices to ensure your system is achieving expected functions all year long

-

Viltra have an admired civils team who can deliver an end-to-end service when needed. This service can implement a complete installation pack from start to finish, saving you the disturbance of executing each element individually.

Our latest projects

Start an OXCRETE PLUS sewage treatment plant project with us

At Viltra, we are specialists in separating waste and water. Whether you have an individual household, a business or a development, we all need and rely on water, we all create and dispose of waste and we all must keep these two worlds apart.

Viltra are a dedicated team who design, manufacture and install wastewater treatment solutions for a wide range of sectors across the UK and Ireland, including the commercial and industrial sector, education sector, conservation sector, domestic sector, agricultural sector and the tourism and hospitality industry. Offering an end-to-end service, the experienced team at Viltra ensure our customers receive a premium service and a robust solution to their wastewater management requirements.

To make an enquiry or to book a FREE site visit by our expert engineers who will find a solution for you, please get in touch with Viltra through the contact form provided.